Driving Innovation in Manufacturing:

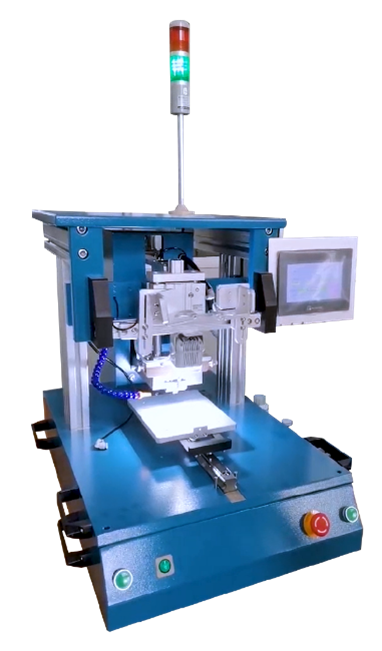

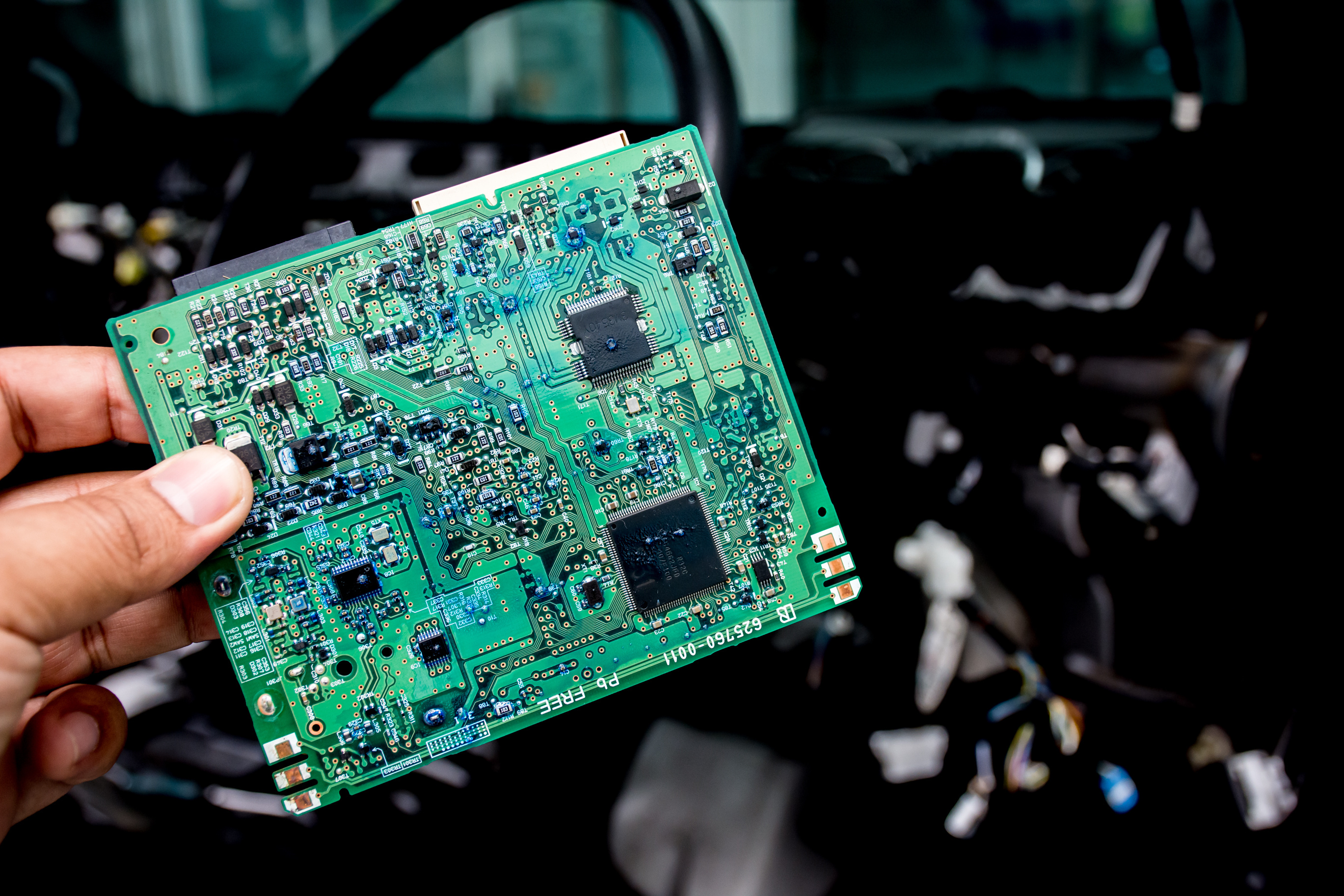

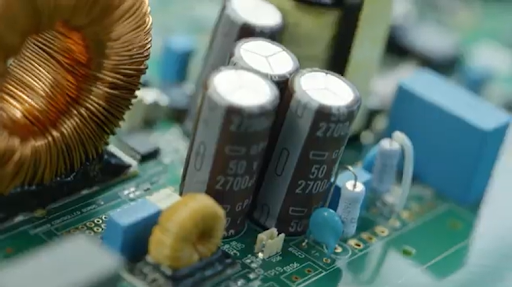

Electronic assembly is a critical process when manufacturing modern devices. Inventive assembly technologies are needed as demand for smaller, faster, and more efficient electronics continues to grow. In recent years, the manufacturing process has been changed by advancements in electronic assembly technologies such as surface mount technology (SMT), automated assembly, and advanced soldering techniques.

Production speeds, precision, and the ability to integrate smaller, more complex electronic devices have been increased by these technologies to meet the changing needs of many industries.

In this blog, we’ll explore some of the top practices from leading assembly manufacturers and highlight real-world examples of success stories that can inspire others in the industry. With solutions, benefits, and RBB's core value of "Always Better" and our unwavering commitment to providing maximum customer benefits. At RBB, we constantly assess our manufacturing processes and seek ways to enhance each task's efficiency.