In Part 1 of this series, you heard about the importance of building a deep bullpen consisting of the right pitchers for your particular needs. You can see that each ballgame will require your starter and your reliever coming in at different times to handle the lineup you’re facing. So… now it’s time to figure out the bullpen of pitchers you’ll bring to the game.

I’ll be the first to admit, that growing up I had zero interest in the electronics manufacturing industry. In my defense, my father became President of RBB in the early 2000s, which was also smack dab in the center of my high school years. Most likely the only types of electronics I was interested in back then were my curling iron and cell phone. But alas, many years have passed since those days and with a couple of business and marketing degrees under my belt... combined with an appreciation for unique businesses that do big things, here I am blogging for RBB.

If you don’t continue to buy from us, bad things will happen. That’s what your current electronic assembly provider hopes you are thinking.

Maybe you remember the Telephone Game from childhood –one person whispers a story or phrase to the next person and tells them to pass it on. They turn and whisper as much of it as possible (as much as they remember!) to the next person, and so on down the line. When the last person has heard the message, they repeat it out loud. Everyone gets a good laugh when the original message is then stated, and all the players realize how distorted it got as it was passed down the line. It’s great fun as a party game; not so great if it’s your training methodology.

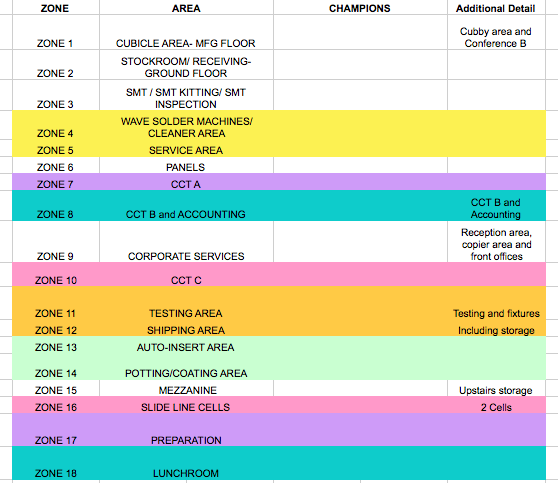

RBB’s 6S Program

Everyone at RBB feels a responsibility for keeping our facility and everything (and everyone!) in it in good working order. We look for every possible way to ensure that the custom electronic boards that leave our facility are pristine, and have been built efficiently and exactly to our customer’s specifications. To do that, we need clean areas so we can focus on the job at hand. We need a well-maintained facility and a dedication to keeping personal spaces as neat as possible.

You’re an OEM who has developed a solid supplier relationship with an electronics job shop, whether they are local or across the country. The shop has proven themselves to be reliable, responsive, and cost competitive, especially in small batches (the work that many of the larger batch CM’s often avoid). You are happy with your job shop’s performance and want to award them more work. What will you do? Let’s explore a few options.

As a large batch contract manufacturer (LBCM), you have enjoyed a high level of success with your business. In spite of this, though, you may have experienced certain situations in which the help of a small batch job shop (SBJS) could have helped you to operate more efficiently and effectively. While you may know that this is true, many LBCMs are hesitant to enter into a partnership with an SBJS, as they are concerned that it will create customer conflict, and cost them money. Reality couldn't be further from the truth.