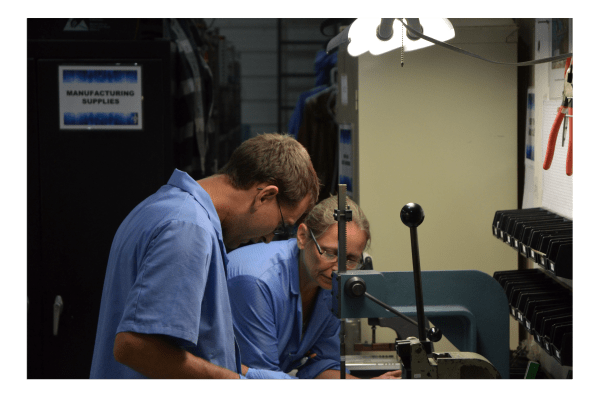

Let's face it - finding a reliable contract manufacturer to handle your small batch orders can be a real challenge. Not only do you need to hire a company with the specific skill sets required to handle your work, but you also need a business that will act as a true partner, paying careful attention to your needs. How can you find the perfect contract manufacturing company? In order to make the best decision, here's a look at eight key things that you should consider when contracting with a third party manufacturer.

I love attending professional development conferences. I really do. I love the change of scenery for a few days, the networking, the enthusiasm, the free food, (c’mon, I know I can’t be the only one) and last but not least: the knowledge waiting to be learned and implemented. It’s always fascinating to see what other companies are doing to market themselves and gain new customers.

In the world of electronics manufacturing, being busy is a good thing, but what happens when your business becomes too busy? In a perfect world, you'd love to have the capacity to keep up with all of your clients needs (and then some!), but in reality, this isn't always possible. This is especially true when your resources become tied up in small batch orders, while clients with larger orders are in need of a rapid turn-around. How can you possibly keep up with everything? This is where having a partnership with a reliable contract manufacturing partner comes in handy. Here's a closer look at how contracting with a small batch electronics manufacturer can help you get out of a tight spot, and thrive.

My last post introduced the “off season” concept, where I made a case that anyone who gets paid for what they do (aka a “professional”) needs to occasionally go away and work on their work. In this post I share my own proven formula for making the most of this time away. I swear by the concept and what it has done for me personally, my businesses, and my family. Treat these ideas as guidelines only; you will find what works best when you get out there on your own.

I've been away from the office this week (but not from blogging!) Find out where I've been and how you can make an off season work for you.

If you’re an electronics buyer, some days you may feel like Sarah Connor at the end of The Terminator, the classic 1984 movie. Remember the unstoppable Arnold Schwarzenegger, in all metal form, as he relentlessly chased Sarah through that factory of moving equipment? He simply refused to die!

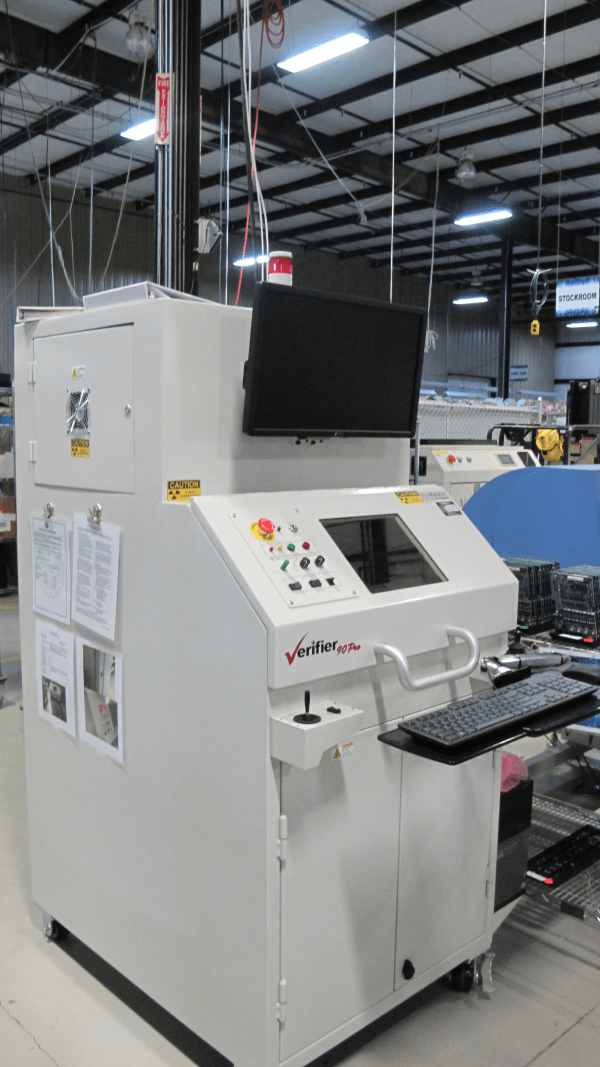

Function of the X-ray Machine

An X-ray machine in micro-assembly inspection is used to see through the first layers of an integrated circuit to inspect the quality of a ball grid array (BGA). It allows us to see and inspect what we wouldn’t be able to otherwise. More specifically, we could see defects in BGA chips, detect possible counterfeit parts, and inspect our special potted assemblies, along with other applications.