In Part 1 of this discussion we discussed 5 battles that small batch job shops like RBB need to fight if and when they occur. Those situations are:

“We exist to move Heaven and Earth to get our small batch customers, what they need, when they need it.” “Even if it blows up the schedule.” A bit of humor, but we’ve all been there, the customer calls and says that they need “WHAT” by “WHEN”. In today’s LEAN electronic manufacturing environment, short lead times and quick turns are essential to our customers. It’s now up to us to make it happen.

Note: This post is adapted from a similar one I wrote for the ODS blog which is devoted to leadership, communication and trust.

Like any business, small batch shops like RBB have many things we can improve upon all the time. (And the minute we don’t admit it signals the beginning of dangerous complacency!) It’s a growing challenge since most low-volume electronics manufacturing companies face intense competition and so seem hooked on instant answers and urgent innovation. Employees, regardless of their formal authority face enormous pressure to address everything that stands in the way of reaching the company's goals. Or they often think they do.

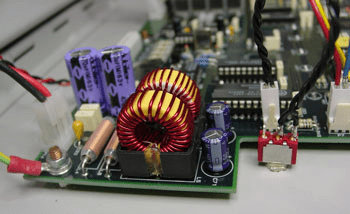

As the Manufacturing Manager at RBB Systems, I oversee the manufacturing of complex circuit boards and custom electronic assemblies, making sure they are built to IPC Standards and are ISO 9001 certified.

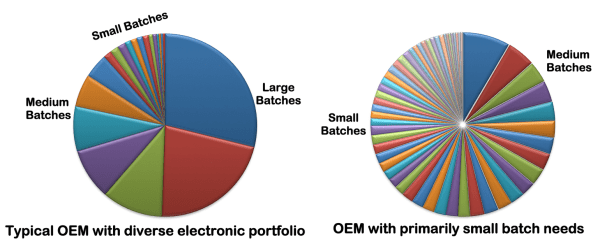

I began my journey with RBB Systems in the summer of 2010. My first home was in the stockroom prepping components and pulling orders for the many different jobs that came through the shop. The one thing I learned very quickly was that no two jobs were the same and the customers were ever changing – benefits to being a small batch electronics manufacturing experts. This was my first experience with this type of work environment. Previously it was mass production. Same parts, same customers. But this was something new that I had never dealt with: many different parts and many different customers.

Talent, class, commitment, and integrity. These leadership hallmarks are exemplified in Wendy Smith, RBB’s General Manager, who begins in May 2013, after 27 years of tireless effort, a new chapter in life. We part as friends and she will be greatly missed. Yet this critical transition will be virtually transparent to customers and the business – and this is a story worth sharing.

At RBB Systems we work with a wide variety of customers that present us the opportunity to build a wide variety of electronic assemblies. This requires us to master a variety of different methods and techniques to manufacture products. Over the past few months the manufacturing department has taken great strides to understand how common and costly mistakes happen, and how to prevent them in the future. This has led us to refine what we have termed the “Kickoff” process.

The Biomedical MEMS and Sensors Conference 2013 held April 16-18 at Lorain County Community College brought presenters, exhibitors and attendees from around the US and the world to focus on MEMS technologies for biomedical applications (BioMEMS).