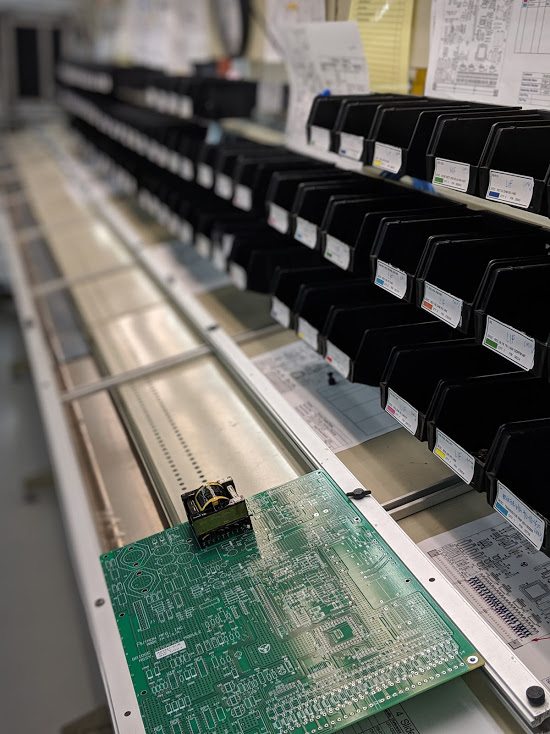

Visual Inspection and Small Batch Electronics

How can a contract manufacturer ensure that it is providing its small batch electronics manufacturing client with the highest quality product when functional testing is not an option? In an effort to reduce costs, many customers will specify that a visual inspection of their completed assembly is to be the final quality control measure prior to shipping. Some of these assemblies can be pretty complex, consisting of hundreds of surface-mount and through-hole components. Each component and its associated solder joints (or another connection method) must be examined. It requires a team of well-trained, dedicated professionals with impeccable attention to detail to successfully complete this requirement.