Circuit board assembly is a proven engineered process. Therefore, developing a consistent process for quoting this service is the first step to insuring success. Following some simple guidelines can lead to more accurate quotes in less time. This is a win-win for any contract manufacturer and customer relationship. Because the completed quote serves as the basis for assembly, initial accuracy is important.

Many of the customers who find their way to RBB or other expert job shops, often do so by surprise. Several industry dynamics put the small batch customer at a disadvantage.

If you operate a business in the made-to-order, small batch world then you face a set of challenges that simply comes with the territory. Whether you’re making cookies, candles or custom circuit boards, by relentlessly improving the following important elements, you can significantly distance yourself from your competitors. They sound obvious – but to sustain an ongoing competitive advantage, they must be approached consciously with a fresh, questioning mindset.

The Importance of Thorough Onboarding

Many companies today are realizing the importance of a thorough onboarding process for their new employees, and are improving their orientation plans accordingly. Getting new employees acclimated to the company quickly is beneficial to both the employee and your company. The first 90 days is fundamental - the behaviors, habits, and attitudes developed during this time will likely determine their success with your company. It’s your responsibility to give them every possible tool, training, and bit of information available so they can hit the ground running.

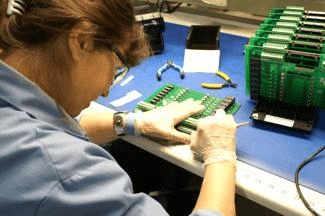

Are you experiencing a significant amount of rework and repair in your commercial electronic assemblies job shop? One of the most common causes is ESD or Electrostatic Discharge. Utilizing safe practices is a must, every electronic shop should be doing so, but first you need to understand what causes ESD.

Mistake #1: Assume That Your Electronic Contract Manufacturer (ECM) Can Read Your Mind!

Your ECM partner works with many customers, each of whom has their own technical standards and style of working. Don’t allow yourself to think that your electronics manufacturer's abundant technical expertise somehow includes clairvoyance!

You Made The Decision.. Now What?

Your company is facing one or more of these situations and has made the decision to outsource the manufacture of electronic circuit board assemblies, control panels and/or box-build assemblies.

Recently, I came across the article "Social Media- Finally Ready for Electronics Manufacturing?" The post was written by Beth Dickinson, a Marketing Consultant for the company TFI, which provides strategic advice and market insights to clients worldwide. The blog post posed the question: What does social media have to offer component distributors, solder-paste makers, and contract manufacturers?

Every organization has its own language. At RBB we use the term swarm to describe how we behave whenever some task or activity needs extra help. But don’t think of kids swarming on

the beach on a summer afternoon. Think instead of piranhas attacking a fresh kill.

Our own special notion of swarming grew out of RBB’s implementation of LEAN manufacturing methods. Simply put, LEAN is all about eliminating anything a customer is unwilling to pay for. Like most small companies who bought into the idea of continuous improvement decades ago, RBB embraced LEAN.

Unfortunately, early results were limited: we implemented many projects (known as kaizen events) before we discovered that LEAN in a job shop environment is simply not the same as LEAN anywhere else. We found that we needed to swarm.

The basic idea is this: we perpetually reassign our people and other resources to where the work is temporarily heaviest. Since job shops like RBB operate in a world with unpredictable/unforecasted demand, we cannot afford to design a rigid, hyper-efficient system for satisfying customer orders. As with card games like gin rummy, the best hand is the one with the most tactical options as new cards turn up. If you’ve ever waited in vain for that one right card to appear, you know what I mean.

As our daily shop floor situation changes, we reconfigure and reallocate resources once again. That’s the other dynamic of any swarm in nature – it changes direction quickly and seemingly effortlessly.

Swarm Killers

Swarming behavior is easy to recognize – you know it when you see it – but it’s almost impossible to describe. So we don’t spend time precisely defining it; instead whenever we see things that prevent us from doing a fast, smooth job of swarming, we take action to knock down these barriers.

Examples of things that can’t coexist with good swarming techniques include:

- Long product changeovers

- Stubborn, inflexible employees

- Stubborn, inflexible equipment

- Specialists that don’t cross-train or share knowledge (aka egos)

- Complicated procedures

- Too many levels in the company hierarchy

- Lack of cash, materials

- Customers who don’t pay their bills

- High employee turnover

All of these cause the swarm to stop everything and ask for directions.

Where Will It Go?

Like real swarms, once the energy is flowing nicely it can be amazing where it will spread. Not satisfied with just swarming on the shop floor, RBB-ers decided to keep going and swarm the new product quoting process as well. And the product documentation system. And the purchasing of materials. And month-end closing. A highly motivated and skilled workforce – with few energy barriers – can combine the best LEAN principles with a hungry attitude.

I can share from personal experience that watching a swarm at work in your company is a joy to behold. But be prepared for the morning when you realize that your job as a leader has completely changed. You now work for the swarm. Your new role: point the swarm, clear away their obstructions, and lead the cheers.

Bruce Hendrick has been a leader of major change in corporations and small business alike for the past 25 years; currently he's the owner of RBB Systems and Organizational Development Services, LLC; noted speaker, author, active church member and community volunteer.