For over 40 years, RBB has existed to move heaven and earth to get our recurring small batch customers what they need, when they need it.

On last Wednesday’s blog, I outlined the similarities between really strong business systems and really great chili. (For those of you who missed the post, find my world famous chili recipe here.) Today, I focus on how to build out really great business system.

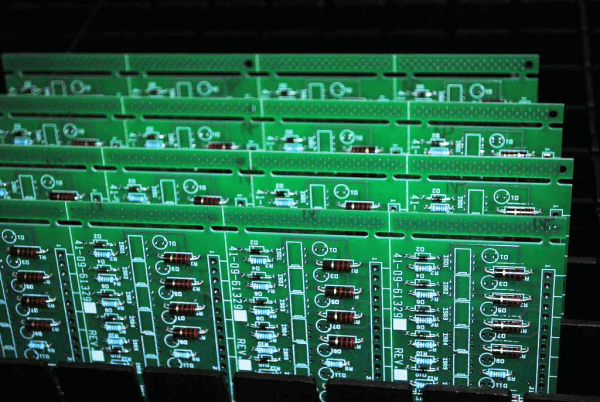

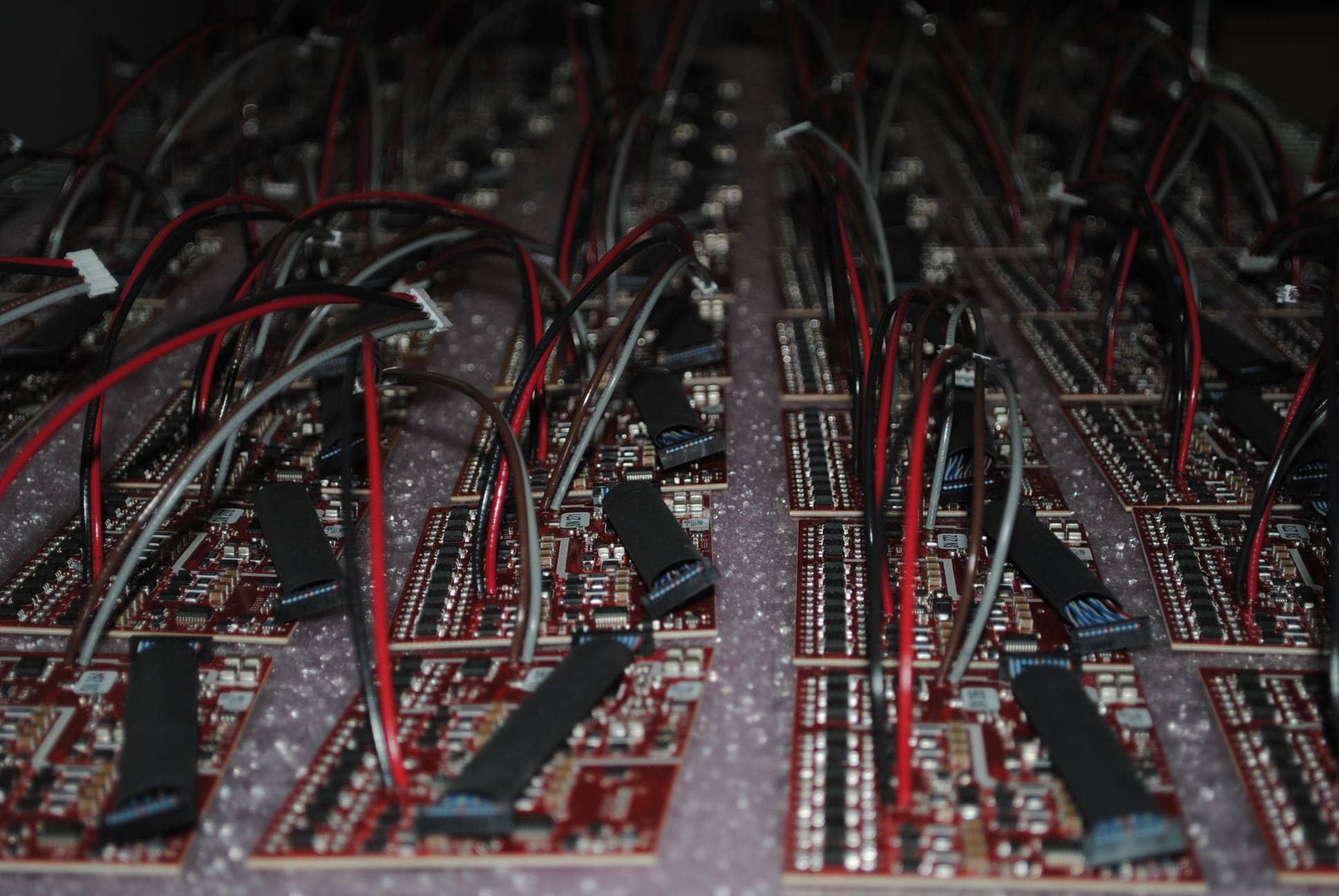

I get a lot of phone calls from entrepreneurs and business owners who are developing a product that has some kind of electronic component. They’re often looking for a new partner to produce parts of the product - or even the entire thing - and are sometimes new to navigating the ways of electronic contract manufacturing.

Embarking on a new outsourced custom electronics project can be full of concerns – and certainly items that you’ll want to have addressed by your outsourcing partner up front. Whether you are an original equipment manufacturer in need of a small batch of custom electronic assemblies for your own product, or a contract manufacturer and want to leverage the volume requirements of an outsourcing partner in order to pass the savings on to your customers, an outsourced relationship is potentially very valuable. As you get started, you’ll want to keep the following seven considerations in mind.