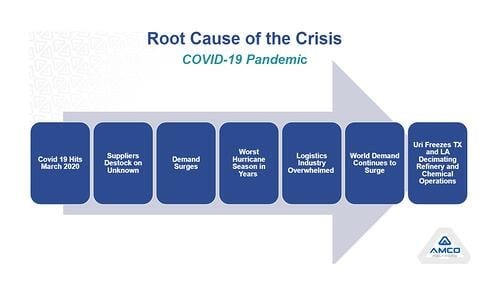

At RBB, our customers are our first priority. As our country continues to recover from the impact of the pandemic, we wanted to reach out to share the challenges we (and many other businesses) are facing. There have been significant raw material shortages and supply chain issues which are contributing to extended product lead times, as well as price increases. As a result of these challenges, you may see some price increases along with varying lead times and product availability. Delivery commitments are given in good faith, based upon the best information present at the time of quotation, but may change due to conditions beyond our control.

Registration is now open for RBB's 2021 Lunch & Learn Series! Each session includes a hands-on presentation, FREE lunch (in person participants only), networking, and RBB facility tour.

All sessions will be held at RBB (1909 Old Mansfield Road, Wooster, Ohio 44691) or virtually.

All are welcome to attend- please pass this invitation to your team members & colleagues!

Does your PCBA manufacturer have heroes? At RBB, we do - every day!

One of our core values is "Move Heaven and Earth." This is how we live our daily lives. We swarm to the need each and every day, getting our small batch printed circuit board and industrial control panel customers what they need when they need it.

We have already hosted three great sessions in our 2019-2020 Lunch & Learn series, "How to Save Money in a High-Mix, Low-Volume World." Our next session, titled The IoT in the High-Mix, Low-Volume World, will be presented by Ed Yenni, President, Logisync via Zoom on October 20.

We have already hosted two great sessions in our 2019-2020 Lunch & Learn series, "How to Save Money in a High-Mix, Low-Volume World." Due to the current situation, our next session will be held in July via Zoom. This session, titled How to Reduce Bare Board (PCB) Costs, will be presented by Jim Thompson & Bob Keisler from National Technology Inc. Jim & Bob will examine board design, cost drivers, and other factors to consider when designing your product.

"How to Save Money in a High-Mix, Low-Volume World"

While our team continues to swarm to get our clients what they need when they need it- RBB has decided to postpone our April lunch & learn session to July 28, 2020. This session is titled How to Reduce Bare Board (PCB) Costs, will be presented by Jim Thompson & Bob Keisler from National Technology Inc. Jim & Bob will examine board design, cost drivers, and other factors to consider when designing your product. This is the third part of our series, "How to Save Money in a High-Mix, Low-Volume World."

All are welcome to attend- please pass this invitation to your team members & colleagues!

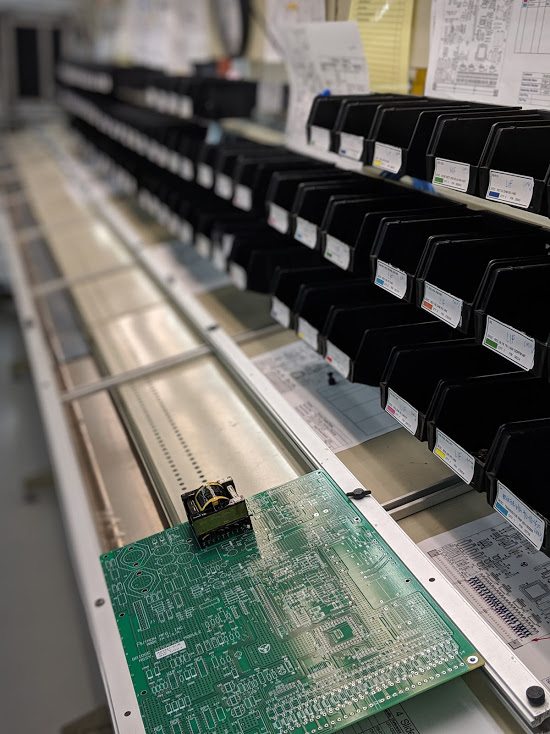

The overall goal of this series will be to educate RBB's partners on how to save money in our high-mix, low-volume PCBA (Printed Circuit Board Assembly) industry. Each session includes a hands-on presentation from RBB team members or suppliers, FREE lunch, questions & networking, and a facility tour.

"How to Save Money in a High-Mix, Low-Volume World"

RBB has already hosted two great sessions in our 2019-2020 Lunch & Learn series, "How to Save Money in a High-Mix, Low-Volume World." In our January Lunch & Learn, Norm Lelless of Future Electronics spoke about Industry Trends in the High-Mix, Low-Volume World. Here is a little summary of what Norm brought to the table:

Design for Manufacturability

Design for Manufacturability (DFM) is the process of designing your product so that it can be produced easily and quickly. A few adjustments can help you get your new product to market before your competition, and help you meet your delivery schedules! The fewer steps in the electronics manufacturing process means less time between ordering and receiving your product.

In the EMS industry, the term high-mix, low-volume (HMLV) refers to CMs or OEMs who change over production between assemblies and processes much more often than their low-mix, high-volume (LMHV) counterparts. HMLV shops convert their lines to different assemblies rapidly (hours or minutes) and frequently (several shifts or days). Note that the opportunity for error rises as batch size decreases.

By contrast, LMHV production runs can last weeks or even months between change overs. It’s a different animal altogether.

RBB builds many hundreds of unique assemblies annually and most weeks introduces multiple new assemblies. It's rare that RBB runs a batch large enough to consume an entire shift of time, much less a few shifts!