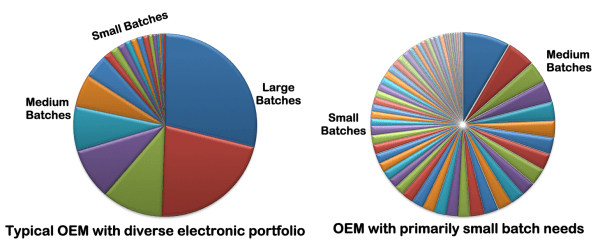

Let's face it - finding a reliable contract manufacturer to handle your small batch orders can be a real challenge. Not only do you need to hire a company with the specific skill sets required to handle your work, but you also need a business that will act as a true partner, paying careful attention to your needs. How can you find the perfect contract manufacturing company? In order to make the best decision, here's a look at eight key things that you should consider when contracting with a third party manufacturer.

In the world of electronics manufacturing, being busy is a good thing, but what happens when your business becomes too busy? In a perfect world, you'd love to have the capacity to keep up with all of your clients needs (and then some!), but in reality, this isn't always possible. This is especially true when your resources become tied up in small batch orders, while clients with larger orders are in need of a rapid turn-around. How can you possibly keep up with everything? This is where having a partnership with a reliable contract manufacturing partner comes in handy. Here's a closer look at how contracting with a small batch electronics manufacturer can help you get out of a tight spot, and thrive.

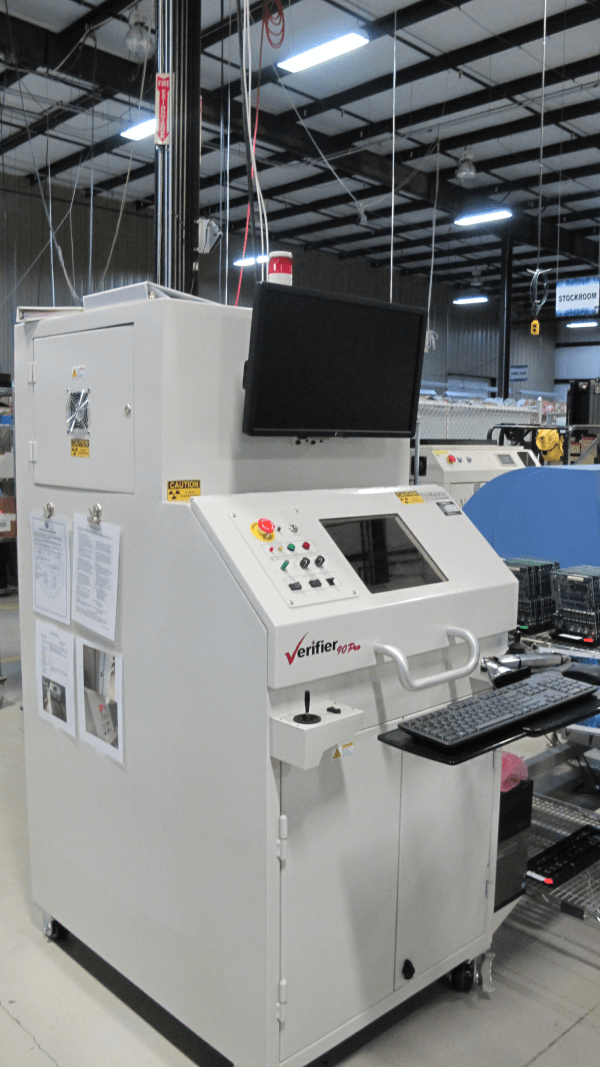

Function of the X-ray Machine

An X-ray machine in micro-assembly inspection is used to see through the first layers of an integrated circuit to inspect the quality of a ball grid array (BGA). It allows us to see and inspect what we wouldn’t be able to otherwise. More specifically, we could see defects in BGA chips, detect possible counterfeit parts, and inspect our special potted assemblies, along with other applications.

In Part 1 of this discussion we discussed 5 battles that small batch job shops like RBB need to fight if and when they occur. Those situations are:

“We exist to move Heaven and Earth to get our small batch customers, what they need, when they need it.” “Even if it blows up the schedule.” A bit of humor, but we’ve all been there, the customer calls and says that they need “WHAT” by “WHEN”. In today’s LEAN electronic manufacturing environment, short lead times and quick turns are essential to our customers. It’s now up to us to make it happen.

Note: This post is adapted from a similar one I wrote for the ODS blog which is devoted to leadership, communication and trust.

Like any business, small batch shops like RBB have many things we can improve upon all the time. (And the minute we don’t admit it signals the beginning of dangerous complacency!) It’s a growing challenge since most low-volume electronics manufacturing companies face intense competition and so seem hooked on instant answers and urgent innovation. Employees, regardless of their formal authority face enormous pressure to address everything that stands in the way of reaching the company's goals. Or they often think they do.

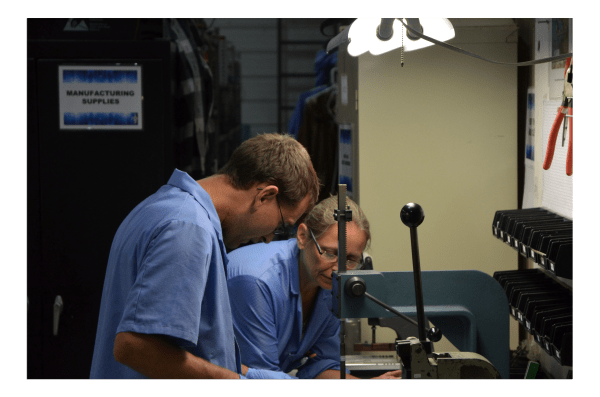

As the Manufacturing Manager at RBB Systems, I oversee the manufacturing of complex circuit boards and custom electronic assemblies, making sure they are built to IPC Standards and are ISO 9001 certified.

-resized-600.jpg)